Tunneling & infrastructure

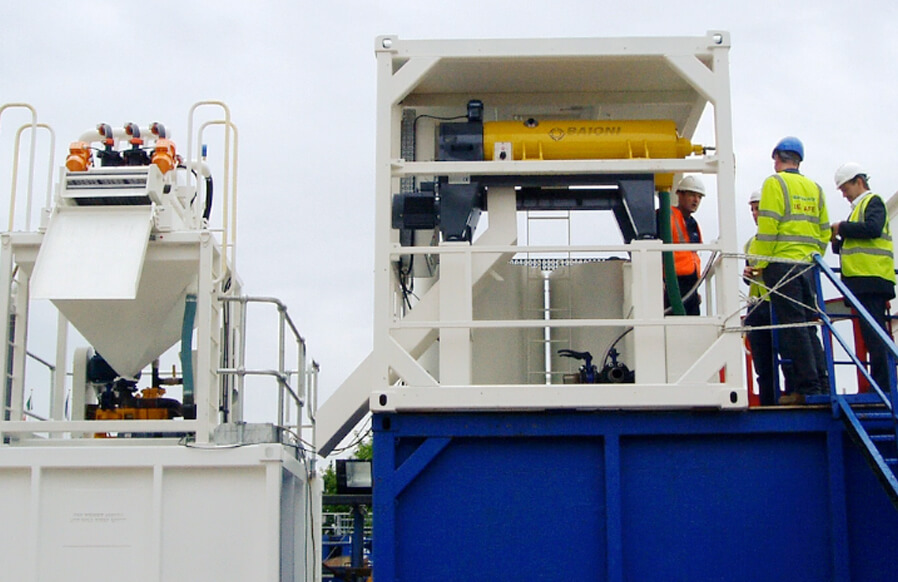

Baioni plant sludge dewatering

Impianti lavaggio inerti per tuneling Baioni

Impianti lavaggio per tuneling Londra

Impianti per tuneling metropolitana

Impianto trattamento terreno per tuneling

Tuneling macchine Baioni

Modern excavation technologies for tunneling and underground works employ the use of a machine with a circular cross section to excavate tunnels called tunnel boring machine (TBM), also known as a “mole”and the use of a liquid sludge containing bentonite to seal the excavated walls. For the tunneling sector and underground works Baioni designs and supplies:

- equipment and plants for wastewater treatment

- equipment and plants for sludge dehydration

Waters coming from the tunnel excavation processes are clarified and finally reused in the aggregate washing processes and then properly discharged.

Why choose Baioni?

- Ability to manage large state works

- Experience in the various fields of application

- Advanced and fast technologies

- Ability to build large plants

It is important to recover the mineral part that would otherwise be lost during tunnel drilling operations as well as to maximize the recovery of waters for further processing cycles.

Sludge must be reduced in volume, therefore they are conveyed onto the dehydration process performed by horizontal centrifuge decanter or filter press. For the drilling and underground excavation drilling sector, Baioni designs and supplies centrifuge decanters for the separation of drilling emulsions for the treatment of water-based and oil-based drilling fluids (sludge). The material entering the emulsion as a result of a drilling process must be separated out: screen and hydrocyclones separate coarse-grained particles, the centrifuge decanter can separate small particles.