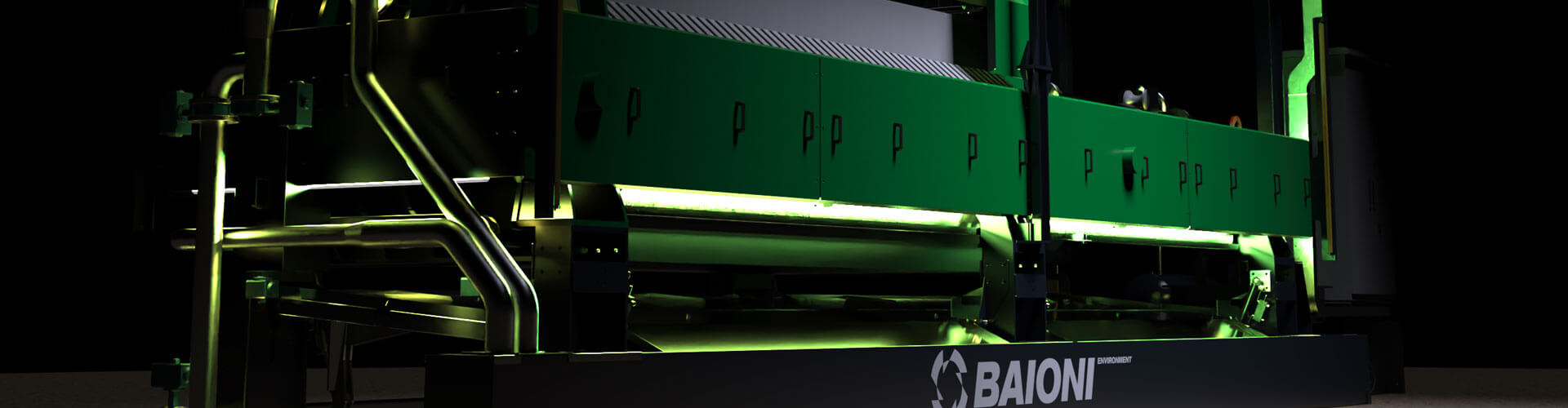

Soil washing plants

ECO-FRIENDLY AND SUSTAINABLE REMEDIATION: A BIG CHALLENGE

Soil washing is an effective remediation technique for contaminated soils which involves the recovery of the valuable part through a process of physical separation of the pollutant present, which results in a multi-stage process with the aim of reclaiming, or washing ‘dirty’ soils, separating them definitively from the polluting element.

Baioni has developed its own process technology offering real complete solutions that can be feasible based on the type of contamination and the final use of the recovered soil. A soil washing plant does not only remediate the material, but it is used to recover the aggregates, sand, clay, top soil and provide these materials back into the construction/development industry.

Baioni soil washing systems are designed and manufactured to remediate various types of contaminated material:

- Diesel range organics (DRO)

- Petroleum range organics (PRO)

- Volatile organic compounds (VOCs)

- Semi- volatile organic compounds (SVOCs)

- Heavy metals (lead, chromium etc)

- Pesticides

- Other toxic substances such as cyanide, TNT, PCB, etc.

Extractive & mining industry

Chemical industry

Production and industrial areas

Landfills

Agro-food industry

Farms

In detail, soil washing systems are made for the treatment of contaminated earthy materials with the aim of recovering the valuable part which, to protect the environment, is identified as an alternative resource to reduce the need for new quarries and landfills.

Each plant is made to measure according to the characterization of the land to be reclaimed with the aim of offering the customer the best technical-economic solution. Baioni designs the contaminated soil washing plants on the basis of the data provided by the laboratory tests that the partner companies carry out on significant soil samples.

Following the analysis, when a soil has a fairly significant inert fraction, the soil washing technique can be used. The process is carried out through a wet separation of the contaminated fraction, from the larger (inert), non-polluted fraction.

The scrubbing process removes dangerous contaminants from the soil and makes it possible to concentrate them in a small volume. This process actually separates the fraction of the soil and the waste that can be treated further.

The recovered aggregates are managed on the basis of their characterizations and can be treated as a product or as waste. In this second case, the resulting product can be processed through suitable plants.

Generally the treatment process begins with the following steps:

- excavation of the soil and the possible storage of the material in a special area

- if the material is suitable, there is a coarse screening of the soil aimed at separating the material according to its size

- the material enters the washing plant where it comes into contact with the various chemical solutions prepared and necessary to improve efficiency in the removal of contaminants

- the following phase of leaving the washing plant involves the separation through a screening process, the sand and gravel from the washing sludge composed of water with contaminated silts and clays

- the next phase, through an analysis, the presence of pollutants in the solid part is verified, then if the removal feedback is positive, the aggregates leave the washing cycle; in the event that the outcome of the feedback is negative, they will be subjected to a new cycle.

The washing water can be used for different washing cycles. At the end of the process it is purified and discharged into the sewer.

Soil and contaminated soil treatment projects involving the soil washing technique require an intense and integrated approach, combining civil engineering, hydrogeology and environmental technology, all elements that are part of the Baioni soil washing technology approach.

- 90% OF AGGREGATES IN THE SOIL IS RECOVERED

- ONLY 10% OF THE INPUT MATERIAL GOES TO LANDFILL

- SOIL RECOVERY OF 60-70% BY WEIGHT, ALTHOUGH IT SOMETIMES DEPENDS ON SIZE DISTRIBUTION